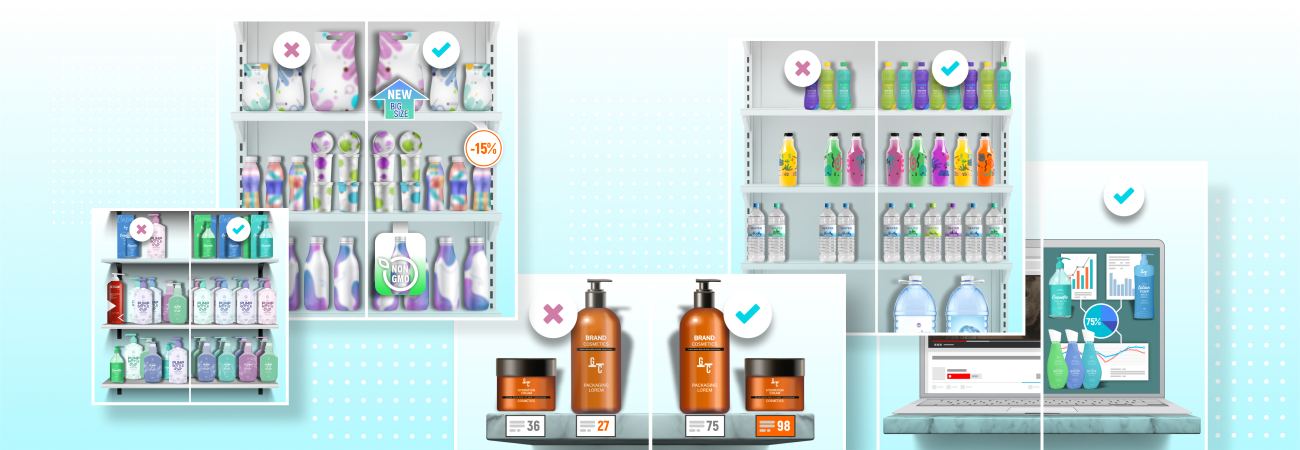

Merchandising is the presentation of goods in a store. FMCG manufacturers and distributors use merchandising tools to manage customer attention and increase sales of the target products. Merchandising tools include the arrangement of racks, a certain layout of goods on the shelves, the location of POS materials (price tags, promotional stickers, wabblers, etc.).

It’s not easy to organize the merchandising process properly. Below we will analyze the most common merchandising mistakes that result in decreasing sales and loss of public image.

Table of Сontents

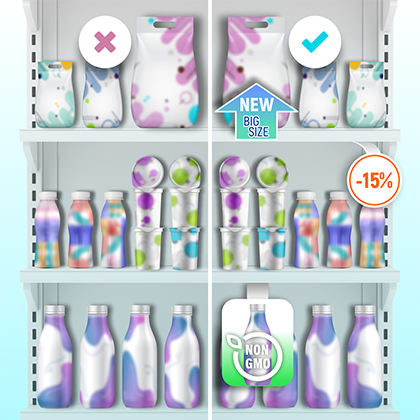

Mistake 1. Non-compliance with planograms

Marketers thoroughly develop their planograms. For example, lesser-known products are displayed next to popular brands, complementary goods are placed together, etc. If the planograms are not observed by the store, then the marketers of the FMCG manufacturer will receive inaccurate reports and arrive at erroneous conclusions. This means that in the future they will not be able to create a competitive marketing strategy.

Case study. According to the planogram, 40% of the shelf should be occupied by a new hair conditioner and the remaining 60% should be occupied by a well-purchased shampoo. In fact, the conditioner is displayed on 20% of the shelf, 70% is shampoo, and another 10% is a competing brand that should not be placed there at all.

But the marketers of the company are not aware of this situation. From the reports, they see that sales are much less than the target figures, and conclude that their assumption about a famous shampoo driving the sales of a conditioner is wrong. And they proceed to planning other marketing activities: promotion on television, incentive games, etc. And these imply completely different budgets.

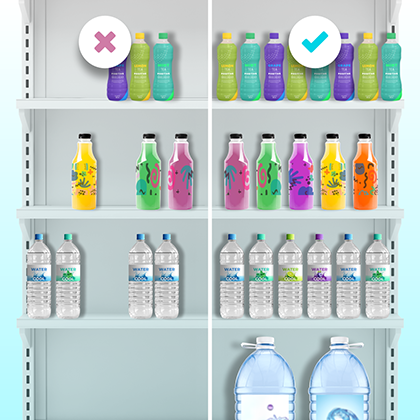

Mistake 2. Empty shelves

Lack of goods on the shelf is a direct loss of sales. FMCG products sell out quickly; consumers are rarely so principled to go to another outlet for a particular brand of sour cream if it is not available in the convenience store. They will put any other brand in their basket. Therefore, it is essential for manufacturers and distributors that the product is always available on the shelf.

There are two main reasons why a product is not on the shelf:

⦁ Store employees or merchandisers failed to put it on the shelf, but the product is in stock

⦁ The product is out of stock.

Each of these reasons needs to be addressed in a different way. In the first case, for example, incentive programs should be developed for employees and merchandisers. In the second case, bottlenecks in the logistics process should be identified and analyzed.

Mistake 3. Mixed up price tags

Wrong price tags for goods are the annoyance of every customer and the most common cause of unpleasant scenes at the checkout.

To avoid problems, it is very important to monitor the accuracy of price tags. The buyer should see how much the product costs, and whether he or she is ready to purchase it for such a price. With a clearly defined price, the company will be able to attract the attention of its target audience.

Mistake 4. Lack of POS materials

POS materials include promotional stickers, stoppers, promotional stands, flags, footprints, and other directional signs that help draw the customer’s attention to the product in the store. Often, buyers decide to buy a certain product spontaneously, seeing an attractive promotion or a product that stands out from the rest on the shelf.

It is important for FMCG companies that their POS materials are present in the store in the pre-designed form. The situation is about the same as with planogram compliance. If the presence and correct placement of advertising materials is not monitored, marketers will not be able to properly analyze their performance.

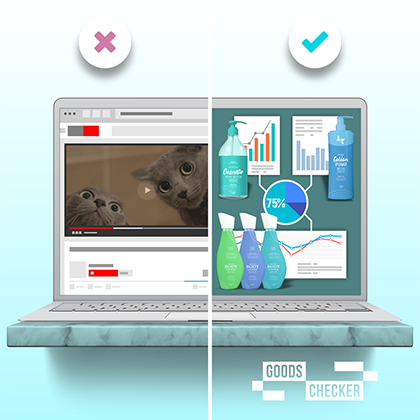

Mistake 5. Incomplete sales analysis

Analytics is the basis for making all management decisions. Analytics answers the question “why?”. It helps FMCG companies to track the reasons for a decrease or increase in sales, to understand the results of marketing activities.

Proper analytics requires the processes to be managed in such a way that marketers obtain up-to-date, accurate and complete data.

Case study. Managers receive a lot of photos and other data from merchandisers. They have to check all the photos in order to objectively and accurately evaluate the work done, to bring all the data together. Based on reports, marketers would like to understand the layout performance and market positions of the company and its competitors.

Often, managers analyze photos from merchandisers for compliance with KPI manually. The process turns out to be labor-intensive and time-consuming, photos are evaluated subjectively. As a result, analytical reports are generated with a delay or based on incomplete data. And this means that it is impossible to understand why a promotion or a change in layout worked the way it did.

Proper processes are the key to successful sales

Getting the merchandising process right is not easy. To do this, at a minimum, you need to establish logistics, arrange supervision over field employees and continuously analyze the results.

To avoid the above mistakes, FMCG companies use IT solutions that automate processes and enhance their efficiency. For example, comprehensive IT solutions, like Goods Checker, cover the entire business process. Merchandisers take a photo of the shelf, and Goods Checker automatically compares it with the planogram and shows which products are properly placed, which goods need to be rearranged, and identifies gaps on the shelf. Based on all marked up photos, the app generates analytical reports. Managers obtain timely and complete data in near real time. Analytics is built with a breakdown by brands, stores, merchandisers.

Automation helps to identify bottlenecks in processes, get more up-to-date high-quality data for making management decisions and enable increased sales