Goods Checker team gave an interview to a leading Ukrainian IT media outlet, discussing Goods Checker – an AI-powered solution for retail audit. Dmitry Akhremcik, Goods Checker Product Manager, shared insights on the system’s implementation, explaining how artificial intelligence is revolutionizing merchandising in retail.

While most companies are still exploring what generative AI could bring to their business, retailers, pharmacies, and cafes have already spent the past three years successfully using AI and computer vision to automate merchandising – monitoring product availability, placement, pricing, and promotional materials on shelves and displays.

Sure, futurists’ predictions about GenAI systems potentially replacing workers capture the imagination. But there are already plenty of real-world examples of computer vision and neural networks simplifying critical routine tasks that would be nearly impossible for humans to handle at scale. Quick, objective monitoring of product availability, shelf placement, advertising materials, prices, and inventory helps FMCG manufacturers, distributors, retail chains, pharmacies, gas stations, and food service establishments increase operational efficiency and revenue. After all, retail profitability depends primarily on having the right product in the right place at the right time. Product placement and pricing directly impact competitive success. Shelf presence is the necessary starting point for countless logistics and retail processes.

Answering a seemingly simple question – is the product on the shelf? – becomes a serious challenge when dealing with dozens or hundreds of SKUs across thousands of retail locations. As businesses scale, the “send someone to look and count” approach breaks down. The time and effort required to gather information, multiplied by inevitable human errors, significantly reduces data reliability and value.

To solve these business problems, developers at IBA Group, represented in Ukraine by IBA Ukraine, created Goods Checker six years ago. This cloud-based system automates every stage of merchandising – from creating and editing planograms to detailed analytics. It recognizes proper product placement and identifies whether products are present or absent on shelves with over 95% accuracy, generates detailed analytics in any required breakdown, and integrates with clients’ BI systems. With Goods Checker, merchandisers conduct store audits faster and more effectively, while analytical reports based on accurate, reliable data are available almost instantly. This enables management to make timely business decisions.

A pilot project typically launches in just a couple of weeks, and shelf and display images can often be captured using existing surveillance cameras.

Goods Checker consists of three main components: Plano Creator for working with planograms, the Check&Go mobile app, and the Shelf Eye computer vision module. The Check&Go app (for iOS and Android) provides essential capabilities for merchandisers – selecting stores and building routes, checking photo quality, stitching multiple images of long shelves when necessary, comparing shelf placement with planograms in real time, and more. It works even with unstable internet connectivity.

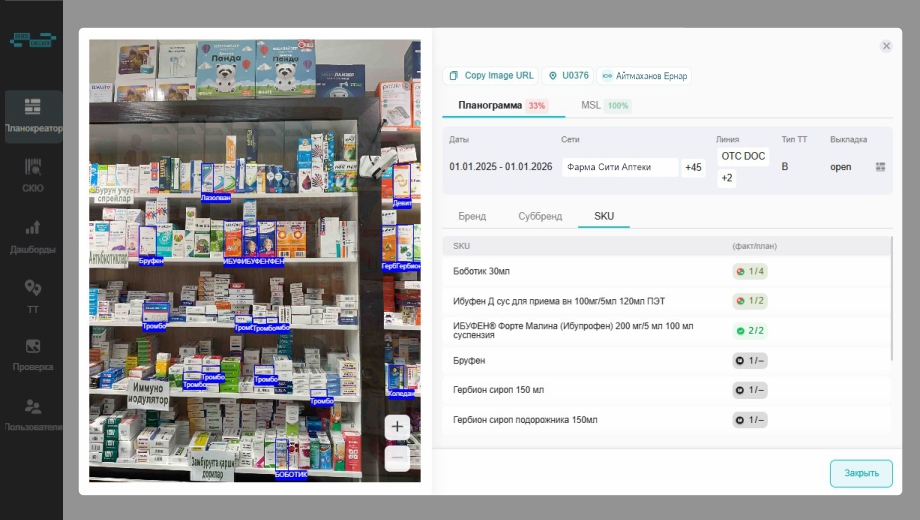

Shelf Eye powers Goods Checker’s core capabilities. This is IBA Group’s proprietary development and key differentiator, based on specially trained neural networks running in the company’s data center in the Czech Republic. Shelf Eye performs shelf image analysis with over 95% SKU recognition accuracy, analyzes price tags and promotional materials, calculates shelf share across various dimensions, evaluates merchandiser performance, compares placement with planograms, and more. Reports update immediately after a store visit, and managers only need a browser to view them.

Although the solution was initially created for one customer, the company decided to offer it as a product service. This benefits clients – they only pay for support and avoid significant upfront costs for infrastructure and specialized personnel. Meanwhile, the developer can freely scale and develop the product while ensuring high quality and fast image analysis.

Here are several real-world examples of Goods Checker implementation across different industries and countries.

Polpharma Santo Case Study

Polpharma Santo is a leading pharmaceutical manufacturer in Central Asia and part of the international Polpharma pharmaceutical group. The company’s portfolio includes around 240 generic drugs sold in thousands of regional pharmacies. Before implementing AI, the company’s medical representatives in Kazakhstan manually analyzed thousands of store photos sent daily by 80 employees. They compared photos with approved planograms and evaluated placement results. Manual analysis covered at best 3% of photos, providing only selective data and preventing objective assessment of product availability. The human factor was inevitable, and planograms were created using non-specialized tools – Microsoft Excel and PowerPoint which complicated the process and consumed significant time.

The Goods Checker pilot project lasted a month. During this time, specialists used historical data and a large volume of images to train the neural network to analyze photos and identify specific SKUs.

After system launch, product placement and monitoring in pharmacies changed dramatically. Now medical representatives arrange products according to the planogram on their smartphone, take a few shelf photos, and get placement comparison results within 20-30 seconds.

Lex Marketing Case Study

Lex Marketing, one of Ukraine’s leading merchandising agencies, works with well-known FMCG manufacturers and international corporations. To increase productivity with existing clients and expand their business, the company needed to optimize processes. They decided to automate one of the most labor-intensive audit stages: checking product placement and availability at retail locations.

For the Goods Checker pilot, they selected 6 cities, 45 retail chains, and 694 stores. Implementation took two weeks and required integration with the client’s existing app. Initially, 12 agency employees worked with the product. After bringing the system into full operation, they scaled significantly – it’s now used in over 4,500 stores throughout Ukraine.

Here’s how the audit works: Merchandisers arrange products on shelves and photograph them through the agency’s existing app. Photos automatically upload to the Goods Checker server, where they’re processed in seconds. Merchandisers immediately see results in their app while managers receive updated analytics. The system shows the real situation at each store and creates analytical reports with the KPIs clients need – planogram compliance percentage, product availability, shelf space share, presence of promotional materials, and more.

Goods Checker has significantly accelerated store audits. Merchandisers now compile audit reports in 20 minutes instead of an hour. The freed-up time can be spent on additional client services or visiting more stores.

Food Service Applications

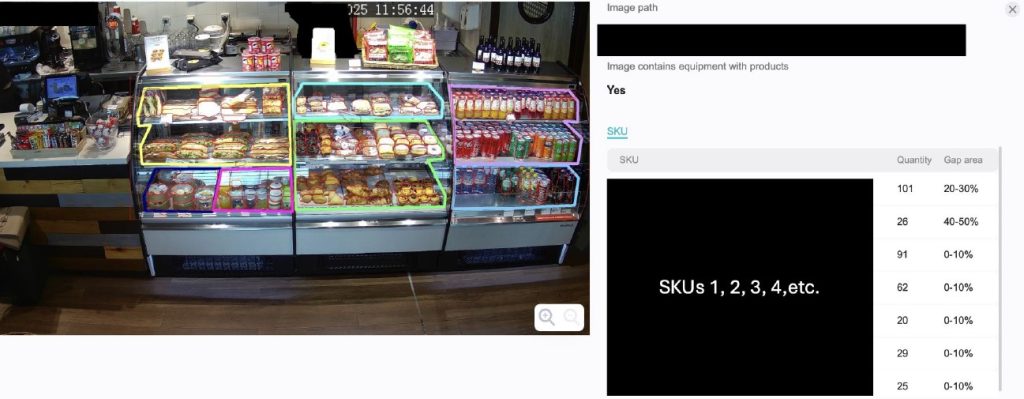

AI can solve many food service problems, including reducing costs, monitoring personnel, and increasing sales. Goods Checker integrates with cafe surveillance cameras to optimize production and product sales, control costs, and minimize losses.

Cafes sell products with short shelf lives – baked goods, sandwiches, confections, beverages. Customers typically buy what’s displayed, so if products aren’t visible, the establishment loses revenue. A computer vision-based system monitors product availability on displays and reminds staff to restock shelves on time. This is especially important at opening, during peak hours, and after closing.

Cafe owners remotely receive data on display fullness for any period and analyze sales efficiency. For example, if displays are empty at lunch and sales are low, the cafe is losing revenue due to missing products. If many products remain at shift end, either the cafe isn’t selling well or it’s producing too much and disposing of leftovers. Goods Checker quickly identifies root causes, helps adjust production, reduce waste, and save on purchases.

IBA Group’s solution has proven effective in several cafe chains in Spain and Portugal, increasing shelf fullness during peak hours from 40-50% to 70-80%.

Conclusion

Projects implemented over the past five years have shown that Goods Checker solution based on computer vision and neural networks allows businesses to automate and significantly optimize merchandising processes.

Additionally, Goods Checker minimizes human error. AI doesn’t get tired, doesn’t lose focus, and works effectively and accurately 24/7. Clients can be confident they’re receiving complete, current, and reliable analytics on store shelf conditions.