Merchandisers are responsible for ensuring order on merchandise shelves. Retailers and manufacturers hire specialists who will audit stores and supermarkets daily. Merchandisers do not only check the display of SKU, their responsibilities include control of the filling of the shelves and monitoring the balances in store. The results of their work are documented by a report with photos of racks and shelves.

The issue of optimizing merchandising, increasing the percentage of planogram compliance to increase sales shall be elaborated by Mikhail Savitskiy, the Tech Lead of the Goods Checker IT retail solution in IBA Group.

Table of Сontents

Manual audit vs. automation

Most retailers have already considered optimisation of the merchandising process and prefer not to audit retail outlets manually. Manual audit methods do not cover all stages of the merchandising process and, therefore, require more time. Moreover, errors are possible, and data obtained may differ from the facts. In addition, the data collected must be manually entered into the corporate system. Manual labour always involves the human factor: even the most diligent and experienced employees can make mistakes. The situation is similar with semi-automation, where IT technologies are used to control some of the processes, but the actions of the machine must still be checked by a human.

State-of-the-art IT solutions can cover the needs of business processes and mitigate the human factor. The entire mechanism of operation becomes transparent for senior executives, the department managers, and merchandisers.

Merchandising automation allows data quality improvement:

- no data duplication;

- consistent form for entering information;

- the entered data are protected from loss;

- the whole process is confidential.

IT solutions will not only help collect and systematize data; they will also provide detailed analytics required by the senior executives with the breakdown by the relevant parameters.

Goods Checker helps to automate merchandising

Goods Checker is an international merchandising automation system. Computer vision and neural networks are used for commodity analysis and to control filling of the shelve. This IT solution covers all stages of merchandising.

Creating goods display rules

Marketing research shows that 40-70% of the purchasing decisions are spontaneous, only 70-80% of buyers finally decide on purchasing goods of a specific brand directly in a retail outlet store. The goods must be placed on a merchandise shelf in such a way that it is clearly visible, attracts the customer’s attention, and finally reaches the cashier desk.

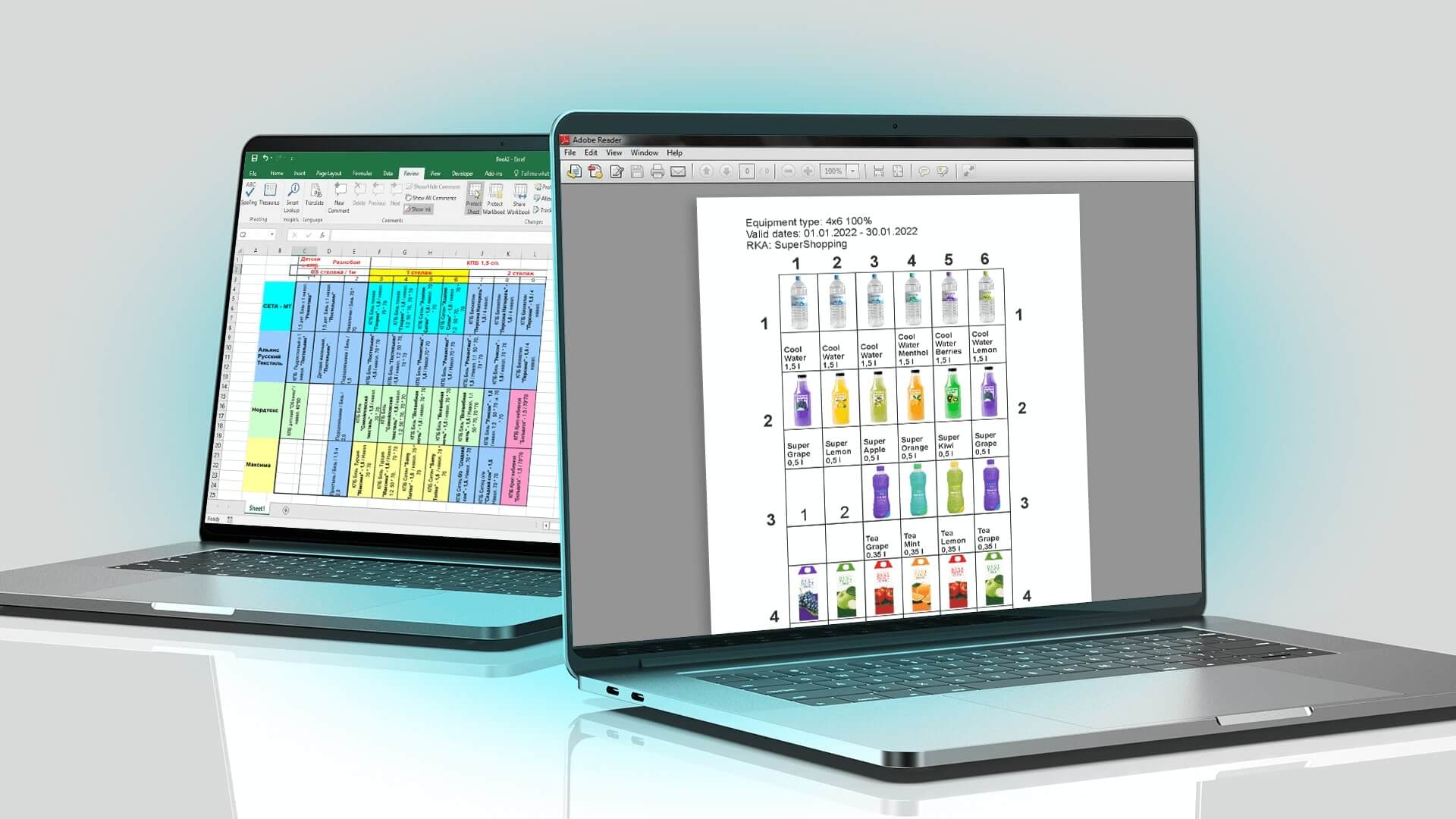

Planograms are the main aid in the correct goods display. When working with planograms, managers use electronic spreadsheets: MS Excel or Google Sheets. An easy interface and availability on every PC are clear advantages.

But there are also several disadvantages associated with building planograms using these tools:

- complex planogram building;

- one has to have constant access to a computer to update the planograms;

- lack of visualisation, as it is difficult to insert an image into the relevant cell.

You can compare planograms created using MS Excel and Goods Checker. The latter has better visualisation: it provides photos, names of the goods, and a clear location on the shelves.

The convenience of Goods Checker is based on drag-and-drop functionality. In such a way, managers can build planograms and save them in MS Excel or PDF format.

Conclusion: it takes less time to create, edit, and update a planogram.

It requires only a couple of minutes for a competent manager to build a planogram including 100 goods items in Goods Checker.

Field work

The efficiency of merchandiser’s work directly affects the sales of a retail outlet. Specialists obtain data in a live situation, which are subsequently used to plan sales and to evaluate actions of competitors.

The responsible representatives of the company and merchandisers mainly use messengers to communicate. Telegram, Viber, and WhatsApp allows setting tasks and supervising over their execution.

But one should bear in mind that messengers have several disadvantages:

- all data appear only in the messenger, they have to be entered separately into the corporate system;

- chats with different employees do not provide an overall picture for all stores in the retail network;

- there may be difficulties arise in organising the work of merchandisers and controlling their movements;

- confidentiality may be threatened;

- all data may be lost in case of a failure.

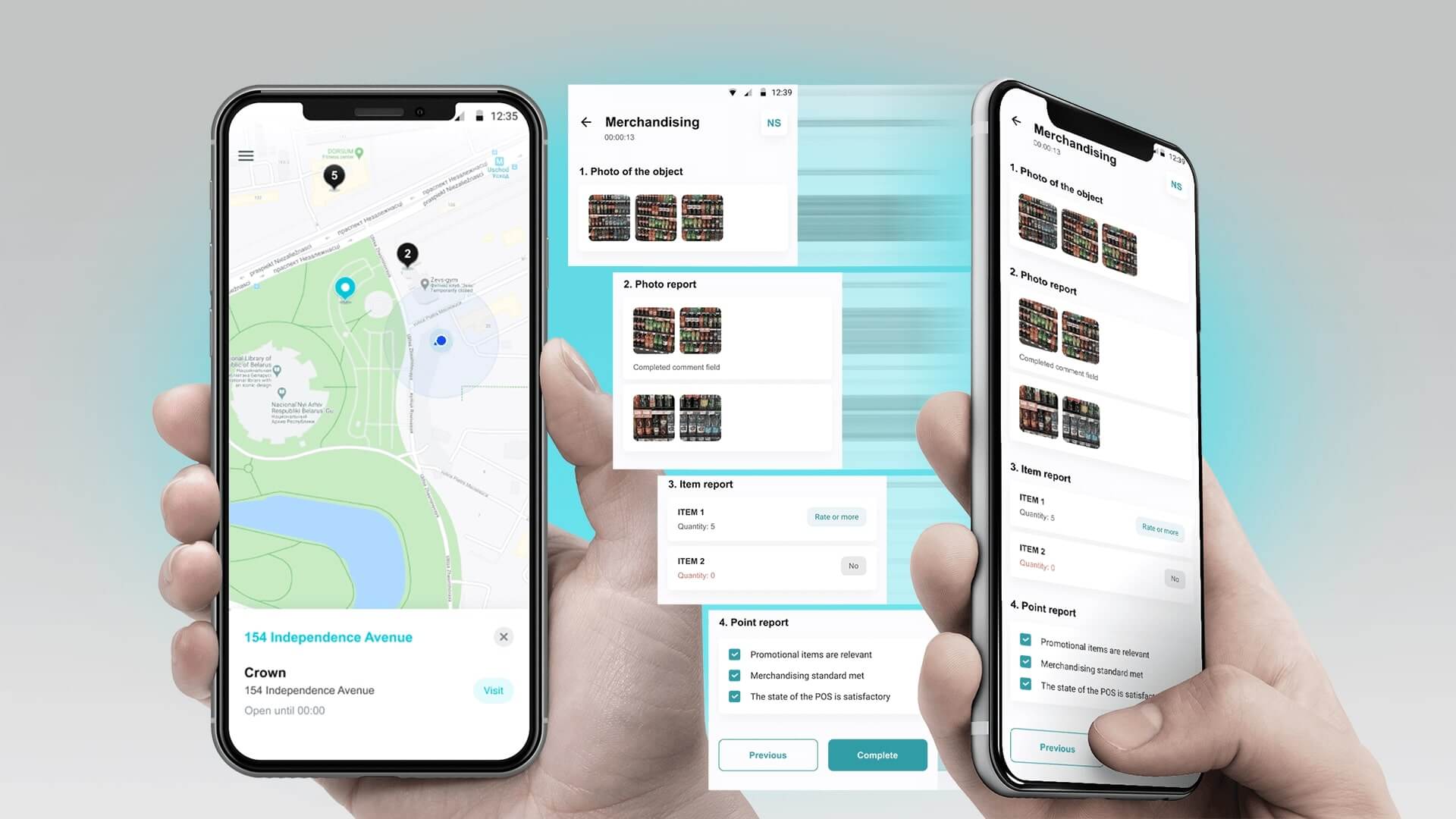

The developers of Goods Checker provided their solution aimed at merchandising automation. They have been focusing on simplifying processes and the ability to control the work of specialists at different stages. To solve the said problems and to automate merchandising Goods Checker presented a web version for managers and a mobile app for merchandisers.

A full-fledged app makes it possible to set tasks and to adjust the merchandiser’s route. Using it, employees can leave remarks and upload photos in the course of work.

A mobile Check&Go is available to merchandisers. It is required to perform managers’ tasks, and to conveniently check the display of goods in real time.

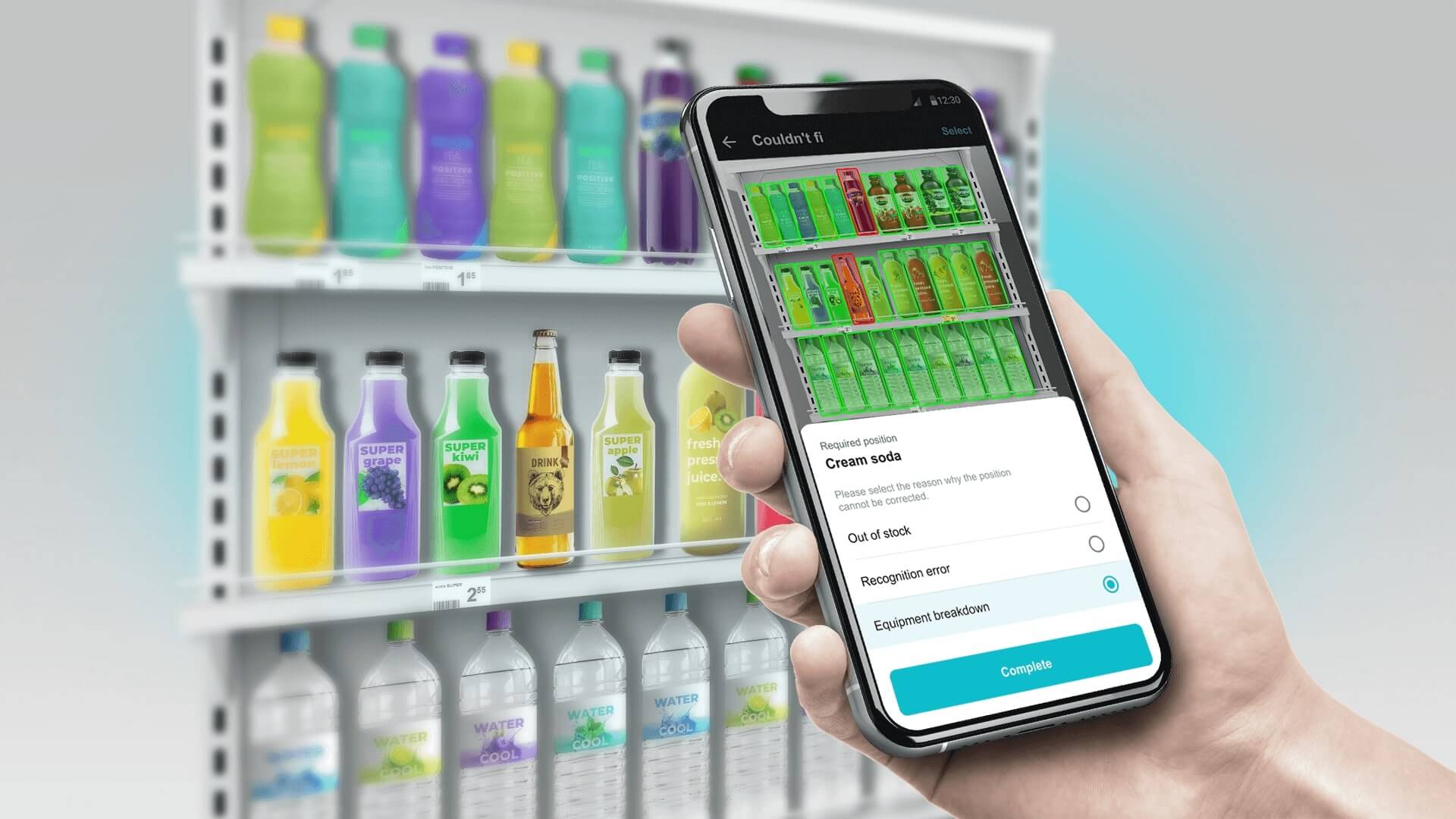

The goods display analysis is AI-aided. The so-called “computer vision” in Goods Checker is able to process a photo, identify the products in the image, compare them with a planogram, reveal any deficiencies, such as in the packaging volume, and give notice on the absence of a particular commodity item on the shelf.

If there are no relevant products in stock or there is any other reason for the deviation from the planogram, a relevant indication is made with a comment.

Check&Go makes all required documents, planograms, and forms easily available. No time is wasted for searching for documents and printing new forms. One cannot lose them and they are protected from errors. The main advantage is that company’s managers can always be sure that accurate and timely information is entered in the system.

Conclusion. Following merchandising optimisation, all employee operations become transparent. Only accurate information is obtained via Goods Checker. It is easier for managers to check and close tasks completed by merchandisers, and supervisors can view photos from the outlets at any time.

The main advantage is that the compliance of goods display with planograms is increased, and the sales of the relevant products grow accordingly. The time the merchandiser spends at an outlet is reduced, so that employees are able to dedicate themselves to other tasks.

Customers share with their success: “Goods Checker has helped to increase planogram compliance from 60% to 90%”.

Analysis and reporting

Preparing analyses is an important process in the operation of an outlet. During a working day, the manager in charge can receive several hundred photos from retail outlets, which are used to assess the merchandiser’s work and to prepare reports. The photos make it possible for the marketing experts to visually assess how the goods display works, what should be changed in it, how competitors work with similar products – these actions for the allow development of a further strategy.

Photos are often reviewed and analysed manually. Such approach is possible when photos are few.

Large retail networks have much greater volumes, and employees are confronted with the following issues:

- managers gradually become less perceptive and evaluation of photos becomes subjective;

- the task is time-consuming;

- it is difficult to prepare final analytics on the performance of a specific employee, group of goods or outlet.

After the decision to automate merchandising has been made, AI comes into play. Goods Checker analyses photos quickly and collects reports based on information from merchandisers.

The form of the final report is easily customisable. It can be presented in several versions:

- with regard to employees – it will show the most efficient employees, the number of stores visited by a merchandiser and the results of the merchandiser’s work;

- with the breakdown by outlets – it will display generalised information on all retail outlets where your branded products are located;

- with the breakdown by product groups – the platform allows you to upload separate analytics for various products;

- in dynamics in relation to the previous period – it will show progress or retrogression.

All reports are available to users of the web app.

Goods Checker allows you to obtain the following data:

- the share of your products on shelves at a given outlet;

- the share of competitor’s products on the shelves;

- reasons for non-compliance with the planogram and the products being not in their place;

- data to calculate employees’ bonuses;

- analysis of photos, showing the level of compliance with the specified SKU arrangement on the merchandise shelf.

Merchandising automation makes it possible to train the system to recognize a new product even before it is placed on the shelves: to do this, you have to load about one hundred photos of the relevant SKU in Goods Checker.

Conclusion. Top managers always see the real situation on the shelves, they can precisely calculate the KPI for each employee and assess the strategy efficiency.

How business automates display control: implementation examples

Goods Checker for automation of goods control in food outlets

AVS Services client offers video surveillance services for retailers and catering companies. Their customers required constant monitoring of the availability of goods on display, but the employees were busy servicing the guests.

Goods Checker was set to identify empty spots on the shelves without preliminary training based on specific goods. The system is integrated with a messenger bot that automatically notifies the staff about the absence of goods of a certain category.

The introduction of the Goods Checker made it possible to establish constant control of filling of the shelves; at the same time, the employees received immediate reminders on the need to supply the goods. It reduced the number of spoiled products and made it possible to optimize procurement planning.

Premium goods display control

A large distributor of food products with a staff of 2,700 employees faced the problem of inconsistency between the planograms and the actual display of products in retail outlets. The existing application was unable to recognize the goods and check the planograms.

Premium chocolates were used for the pilot project. For 3 months, the developers trained the computer vision models, while another 1.5 months were spent for field testing of the system.

The introduction of Goods Checker made it possible to boost the compliance with the planograms from 60% to 90%, significantly reduce the audit time thanks to fast and accurate processing of photographs (not exceeding 30 seconds per photograph). The managers obtained a transparent display monitoring system, which made it possible to improve the interaction with sales networks regarding representation of products.

A case with a juice producer

The products of the brand are sold in 10,000 stores. The stores are visited by 150 merchandisers, who adjust the display, assess the quantities of goods remaining in stock, take photos of the shelves and send them to the manager.

On a monthly basis, a manager receives and processes about 80,000 from various retail outlets. It is physically impossible, so a decision was made to automate merchandising.

After Goods Checker has been introduced, the number of analysed photos has increased from 5% to 100%. In addition, Goods Checker helps to evaluate the merchandisers’ performance and identify and deficiencies in the placement of goods on the shelves.

Automation penetrates modern business

Modern companies need innovation to simplify work processes. Merchandising is a significant link in the sales chain; resolving bottlenecks in merchandising will make it possible to boost sales by 5-7%.

Goods display control automation solves several tasks at once: it reduces the effect of the human factor, accelerates collection and analysis of data, improves the accuracy of reporting and ensures transparency of all processes. As a result, companies not only optimize staff costs, but also get a tool to improve the efficiency of sales thanks to timely control of goods on the shelves.

Introduction of modern technologies to merchandising is no longer a matter of choice; it is a necessity to remain competitive in the market. The first companies to automate these processes gain a significant advantage over others regarding the speed of decision-making and the quality of cooperation with sales networks.